[85] Multiphysics simulation of paper curl due to moisture transport

G. H. Yoon, B. Yoo, W. K. Kim, J. Woo, T. Kim, and S. Lee. Journal of Mechanical Science and Technology 34 (2020): 2075-2083.

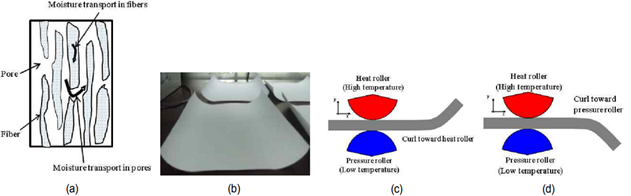

The moisture transport at the fuser nip of printers is postulated to be the main reason for paper curls. However, the fundamental mechanisms of paper curling remain unclear. Observing the moisture transport inside a sheet of paper through experiments is difficult because moisture transport rapidly occurs in a micro-scale thickness. Therefore, developing a theoretical model is crucial to understand the mechanisms of paper curling and to control the curls. In this study, we proposed a multiphysics model that includes the moisture and heat transport and mechanical deformation. The elasticity, plasticity, viscosity, and expansion caused by moisture were considered in the mechanical model to describe the complex material characteristics of paper. The curvature of curls was calculated using an effective two-spring model. The mechanisms of curling in printers and the direction of curls were understood through finite element simulations. The proposed model can qualitatively predict the paper curls observed in experiments. The temperature- and moisture-dependent material properties of paper will be studied in the future to improve the proposed model.